| CRANE SOLUTIONS |

| |

| GALVANIZING CRANE AUTOMATION |

|

|

|

|

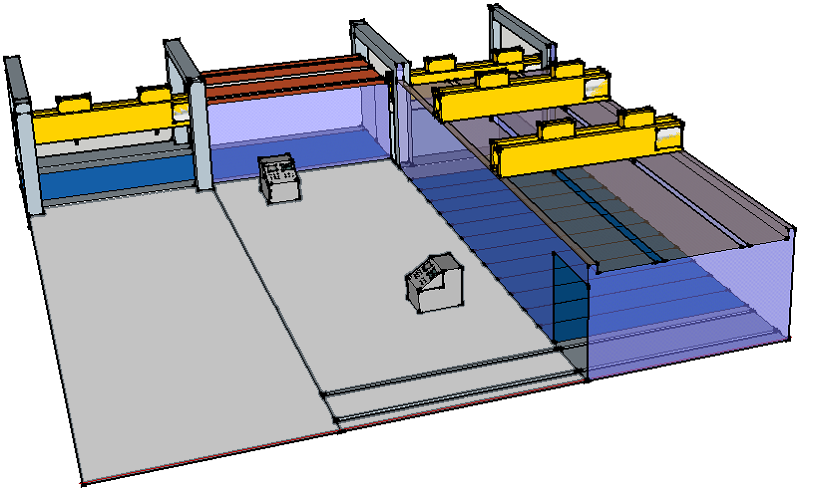

Description

Galvanizing line consist of four sections, Acid pools, Drying, Hot dipped, and passivation.

Firstly tructural materials carrieages via Transfer hanging and are kept in the acid pools with help of cranes. After a certain time , the materials in the drying oven and as later during the galvanizing process is immersed in the pool. This is done after the passivation process and thus the process is completed.

System is controlled by two separated sequences porgram via PLC . All cranes can be work automatically and manualy.

|

|

Products

Frequency Drive + Encoder

Opt.

10'' HMI

L CPU +DI,DO,AI Module RS485/422 Com. Module

Wireless Ethernet Gateway

Absolute Lineer Encoder

Rotational Encoder

Brake Resistor

Load Cell

CCTV

|

|

| ROLLINGMILE CRANES |

|

|

|

|

Description

Rollingmiles are high tonnage cranes. Generally, these cranes are made through a single shaft load sharing with two engines shown below. Two frequency inverter work as master and slave. Slave inverter follow master inverter also shaft controlled as a single engine.

|

|

Products

Frequency Drive + Encoder

Opt.

Brake Units

Brake Resistor

Load Cell

Remote Control

AI,AO Option Card

|

|

| |

| TOWER CRANE |

|

|

|

|

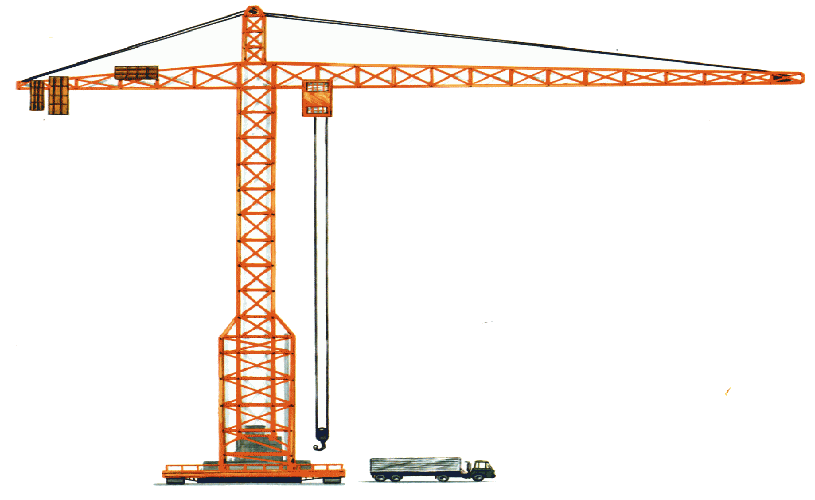

Description

Below specs shown in 7'' HMI

• Actual Load

• Distances of trolley

• Rotation angle

• Wind speed

• Total working time

• Limit load according to trolley distance.

• Alarms

• All motors Current, Speed, Frequecy

• Maintenance timers

• Black box( Logged all actions every second for 10 year)

|

|

Products

Frequency Drive + Encoder

Wind rose

HMI

PLC

Encoder

Remote Control (Optionall)

Load Cell

Joystick

Brake Resistor

Brake Unit

|

| |

| |

| GANTRY CRANE |

|

|

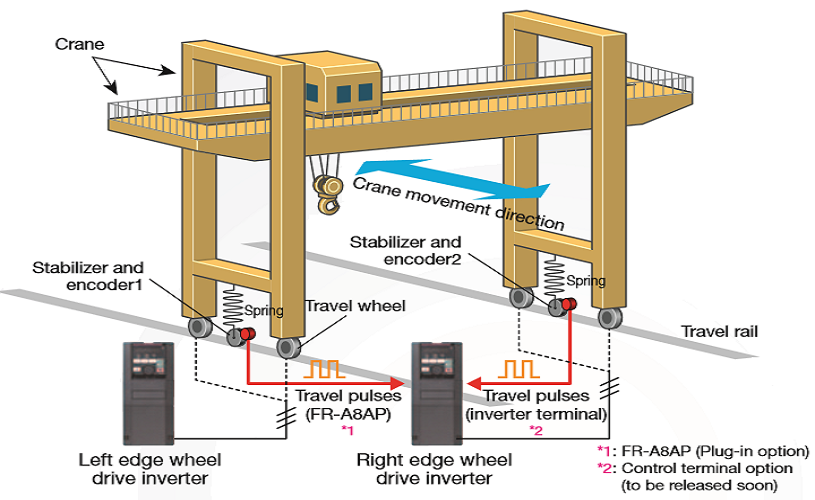

Description

Gantry cranes are a type of crane built atop a gantry, which is a structure used to straddle an object or workspace. They are also called portal cranes, the "portal" being the empty space straddled by the gantry. The terms gantry crane and overhead crane (or bridge crane) are often used interchangeably, as both types of crane straddle their workload. The usual distinction drawn between the two is that with gantry cranes, the entire structure (including gantry) is usually wheeled (often on rails).

Frequency Inverters have special crane macros. Most importans are

Antisway funciton for trolley, and Regenerative brake.

Antisway application video

Especially over 20 ton cranes strongly recommended to use regenerative frequency inverter for energy saving.

|

|

Products

Frequency Drive

Brake Resistor

Brake Unit

Encoder Card(Optional)

Load Cell(Optional)

Remote Control

Load Monitoring(Optional)

|

|